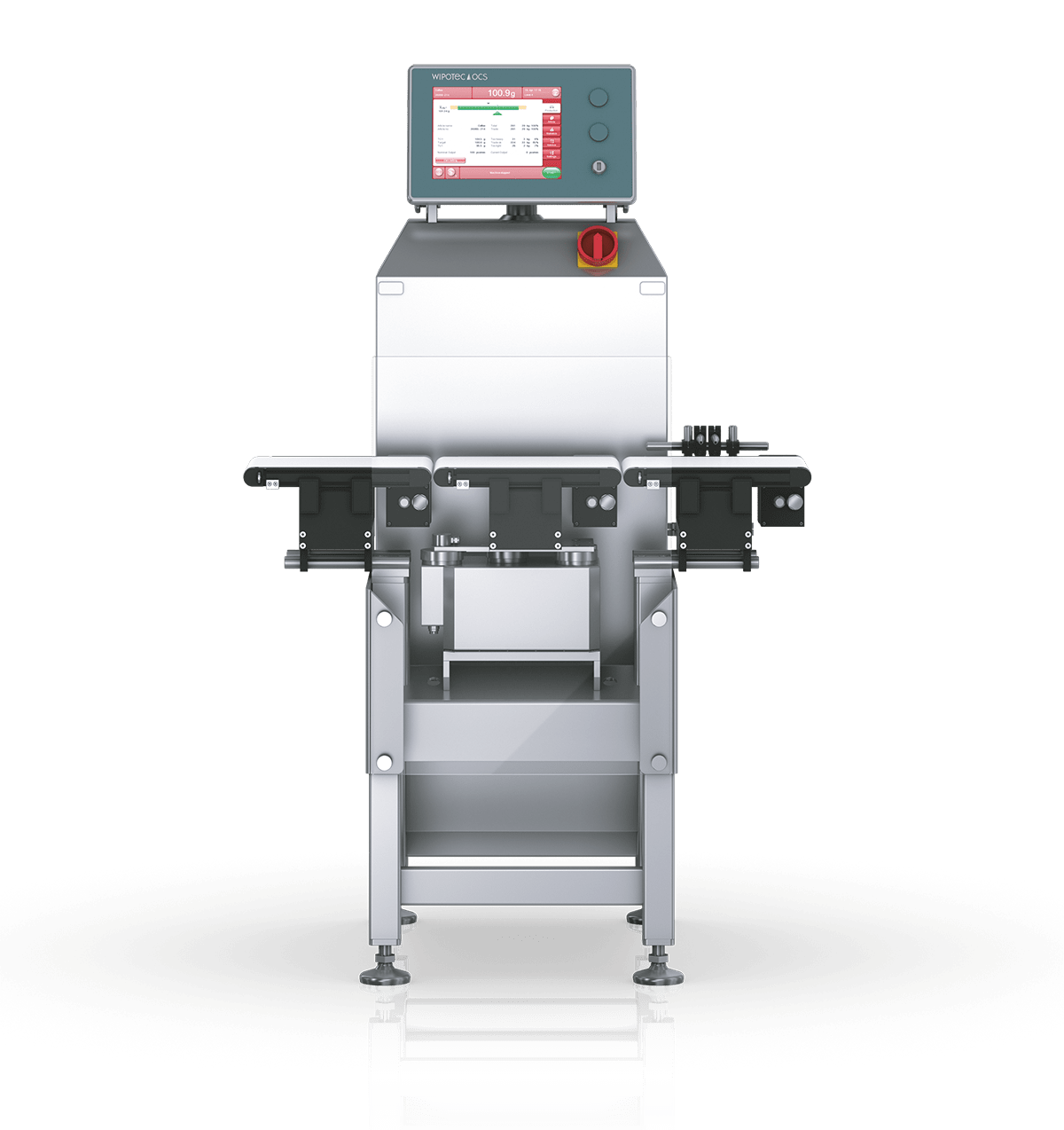

In terms of precision and throughput, checkweighers of the HC-A series are the logical response to meet the demands of modern, dynamic weighing technology. The machines provide the controls and engineering to create the ideal platform for implementing the complex regulation and control tasks.

The HC-A is the basis for high end application-oriented systems that provide a maximum of 600 values per minute with 100% product monitoring. This model significantly extends the application possibilities of the product line and completes our versatile product range, especially for high-end applications. In particular, the advanced solid stainless steel frame ensures extremely accurate weighing results at very high transport speeds or throughput rates. The modular design facilitates the implementation of custom solutions for a variety of product geometries and forms.

The sophisticated and wide selection of sorters (pusher, air blast, etc.) is designed to reliably eject products with incorrect weights with respect to packaging. The HC-A is characterised by its comprehensive product hand¬ling. For example, the top runner belts safely perform acceptance and acceleration of folded cartons just as the metering screw and lateral pressure belts safely separates and accelerates vials and bottles.

The HC-A supports your efforts to minimise costly overfilling with a number of optional functions.

KEY FEATURES

- Sturdy, solid stainless steel frame

- One sorter (air blast or pusher)

- Maintenance-free servo-drive

- Certified (MID)

- Wipotec EMFR Weigh Cells

- Simple, menu-directed operation via a

- 15“ colour TFT touchscreen

- Easy, tool-free exchange of belts and conveyors

- Flexible integration in production lines

- Line synchronisation with potential-free

- I/O signals (expandable option)

- Variable conveyor belt widths and lengths

- Extensive statistical functions/histograms

YOUR BENEFITS

- Max output 600 ppm

- Exact fill results for highest productivity

- Efficiency improvement through simple and user-friendly controls

- Requirements-based modularity for the

- greatest flexibility

- Greater unit efficiency means a positive

- contribution to reducing TCO

Ask about the product

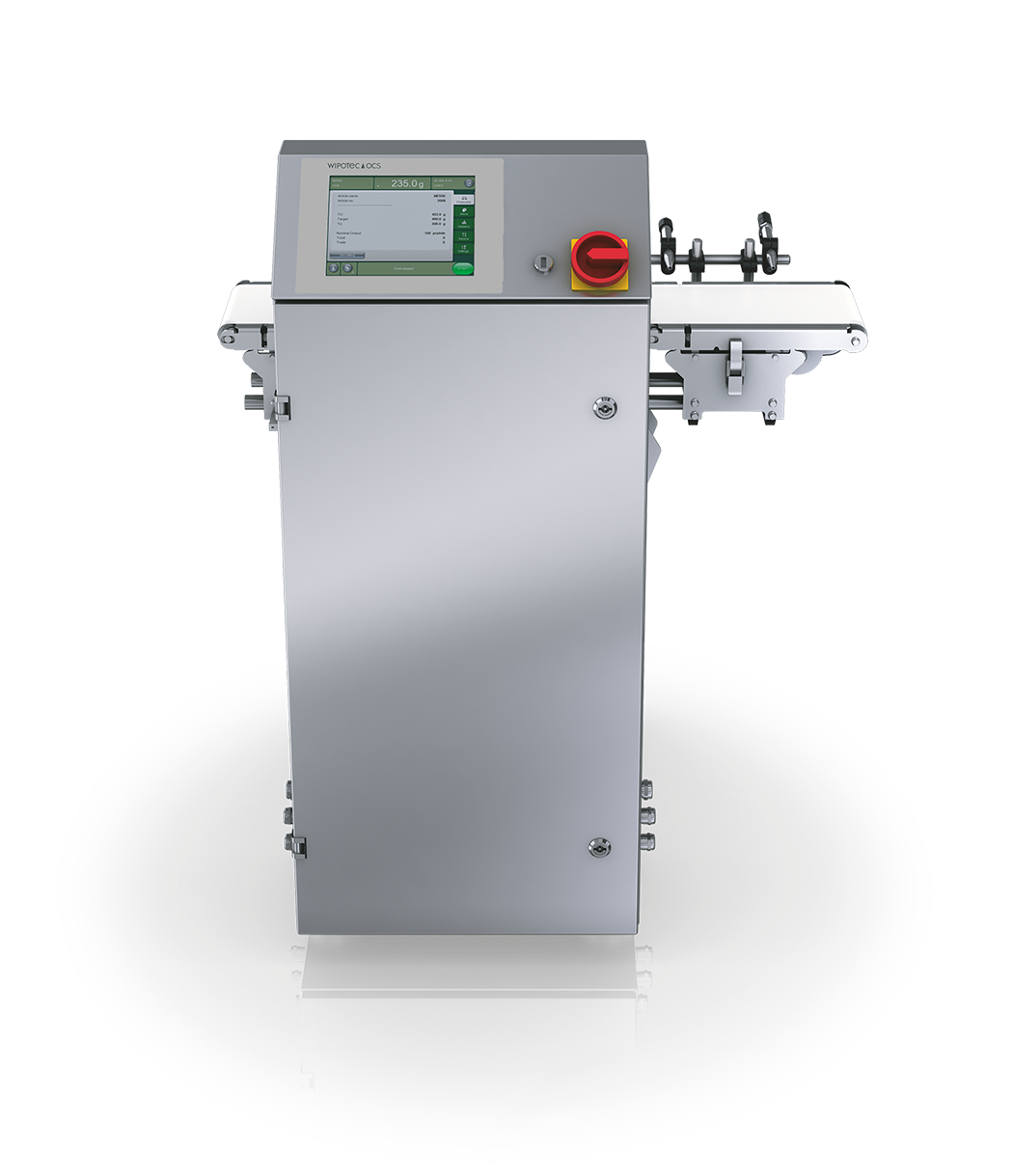

HC-A-VA

Top quality components for your success

The HC-A-VA dynamic checkweighers in solid stainless steel provide the highest standards of precision and maximum throughput. This means the HC-M-VA (protection class IP65) is ideal for use in light to average humidity environments and easily integrated in existing production lines. As machine components, the weigh cells, motors, and conveyors are also constructed from stainless steel. The use of high-tech Weigh Cells, which operate according to the principle of Electro-Magnetic Force Restoration (EMFR), guarantees optimal weighing results with the best technology.

KEY FEATURES

- Complete construction in stainless steel

- Extensive statistical functions/histograms

YOUR BENEFITS

- Efficiency improvement through simple and user-friendly controls

- EMFR Weigh Cell for precise weighing results

HC-A-Multilane

High performance checkweighers for multi-track operations

The HC-A multi-track systems are particularly well-suited for use with small package sizes (for example, stick packs or 4-sided sealed bags). Multi-track units are available in conventional conveyor belt systems and also as a push over variant. High-precision weight measurements with individual display are provided for each track (with the minimal mid-lane positioning). The rejection system can be track based or combined. In the push over variant, the EMFR-Weigh Cell is completely decoupled mechanically from the product transport. Products are pushed by a „finger“ (guided and driven from above) onto the weighing platform. The product transport is centrally managed by only one servo drive for the entire checkweigher (all tracks).

The smallest feasible track separation and maximal accuracies are achieved using the push over method. Multi-track units are custom designed, developed, and manufactured to your specific requirements, dependent on the filling unit in operation and the product geometries.

KEY FEATURES

- High-precision weighing of small packages

- Automated 100% in-line-control

YOUR BENEFITS

- Compact design for easy integration

- EMFR Weigh Cell for precise weighing results

HC-A-Mi

Precision weighing for the lightest objects

The HC-A-MI is the perfect automated system for continuous and accurate weighing of ultra-lightweight parts (for example, stick packs) in the milligram range. Product infeed is product-specific and individually managed. Vibrations in the production environment are suppressed through preload adjusted noise compensation (optional). Weight values are determined within fractions of a second. The classification of either accepted or rejected products, as well as the subsequent sorting, is done directly by the controls of the checkweigher. Because of its automated 100% monitoring, the HC-A-MI provides new possibilities in quality assurance for sensitive products and production processes. It is easily integrated into any production line. The use of high-tech Weigh Cells, which operate according to the principle of Electro-Magnetic Force Restoration (EMFR), guarantees optimal weighing results with the best technology.

KEY FEATURES

- Highly precise weighing in the milligram range

- Automated 100% in-line-control

- Available as multi-lane version

YOUR BENEFITS

- Max. output 200 ppm

- Flexible integration in production lines for more efficiency

HC-A-MDi

Weighing plus metal detection for maximum product safety

The HC-A-MDi model is synonymous with high precision weighing in combination with extremely sensitive metal detection for optimal performance. It is a practical combination of inspection technologies in the interests of increased consumer safety and provides scales and metal detector in one space-saving unit, which can be operated from one HMI and easily integrated as part of any line. The use of high-tech Weigh Cells, which operate according to the principle of Electro-Magnetic Force Restoration (EMFR), guarantees optimal weighing results with the best technology.

KEY FEATURES

- Easy operation of both inspection units via one HMI

- Extensive statistical functions/histograms

YOUR BENEFITS

- Integrated metal detection for extensive control

- EMFR Weigh Cell for precise weighing results