How, for who and what is possible

Track & Trace begins with the right advice on how the TQS system implements country-specific regulations. On this basis, our project engineers work out the best possible machine and line configurations with you. They support you throughout the order processing and help later on, along with our service department, in the installation of your production lines. This approach ensures project and customer-specific requirements are met and, equally, respected for a timely project completion.

TQS Systems (Traceable Quality Systems)

Marking and verification systems product portfolio

HIGH PRECISION PRODUCT TRANSPORT ENSURES OPTIMAL PRINT QUALITY

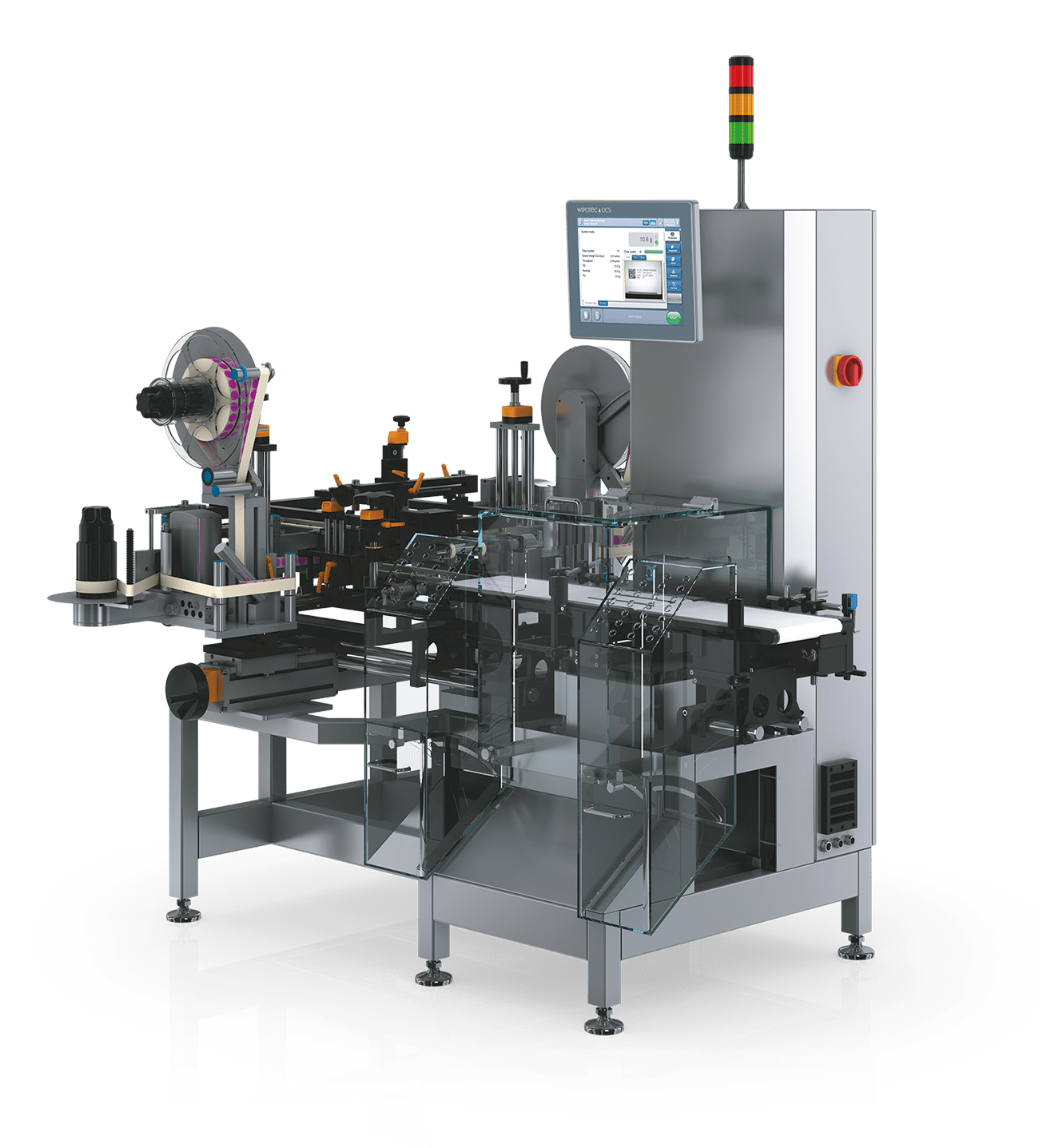

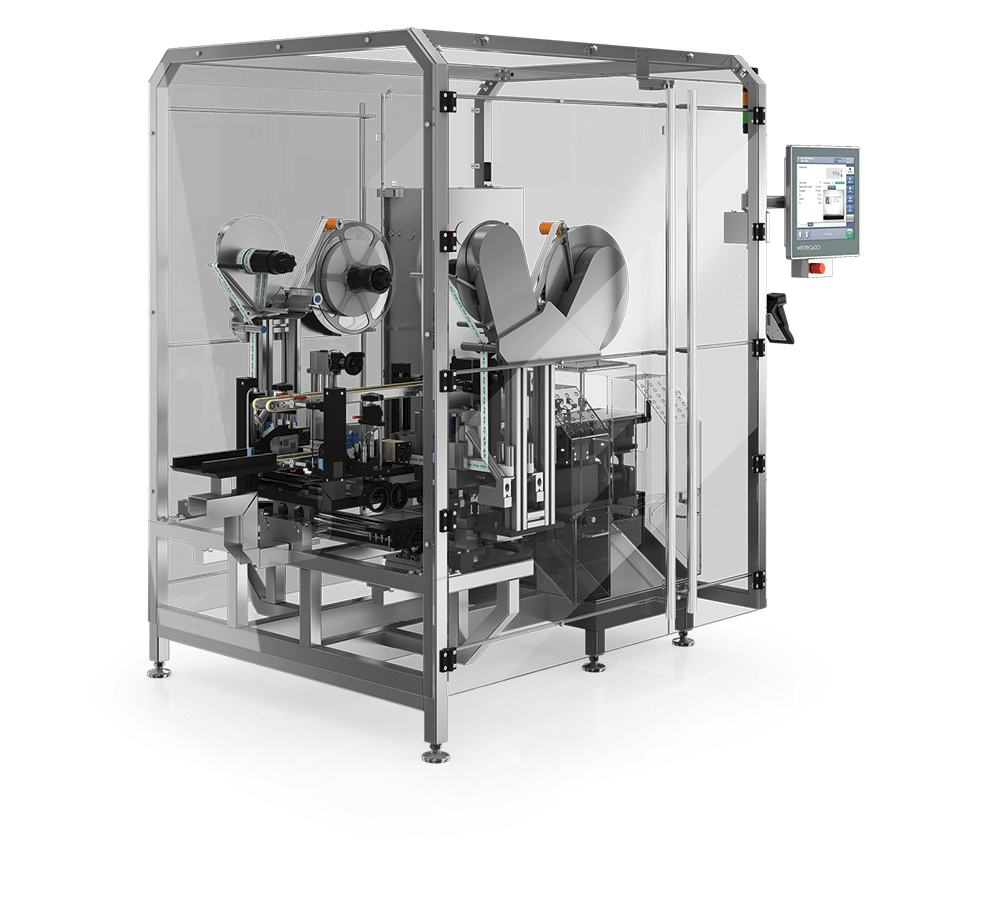

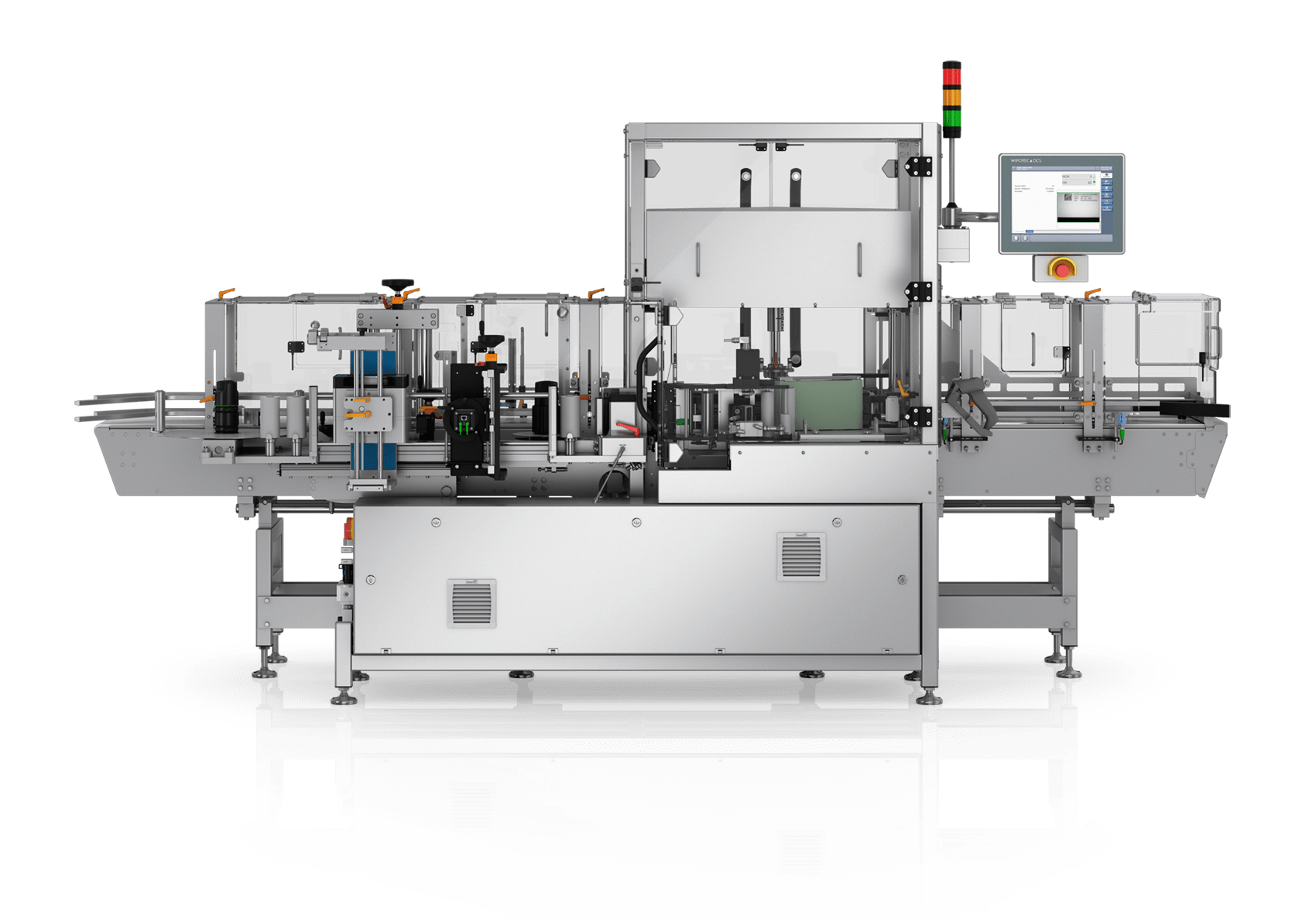

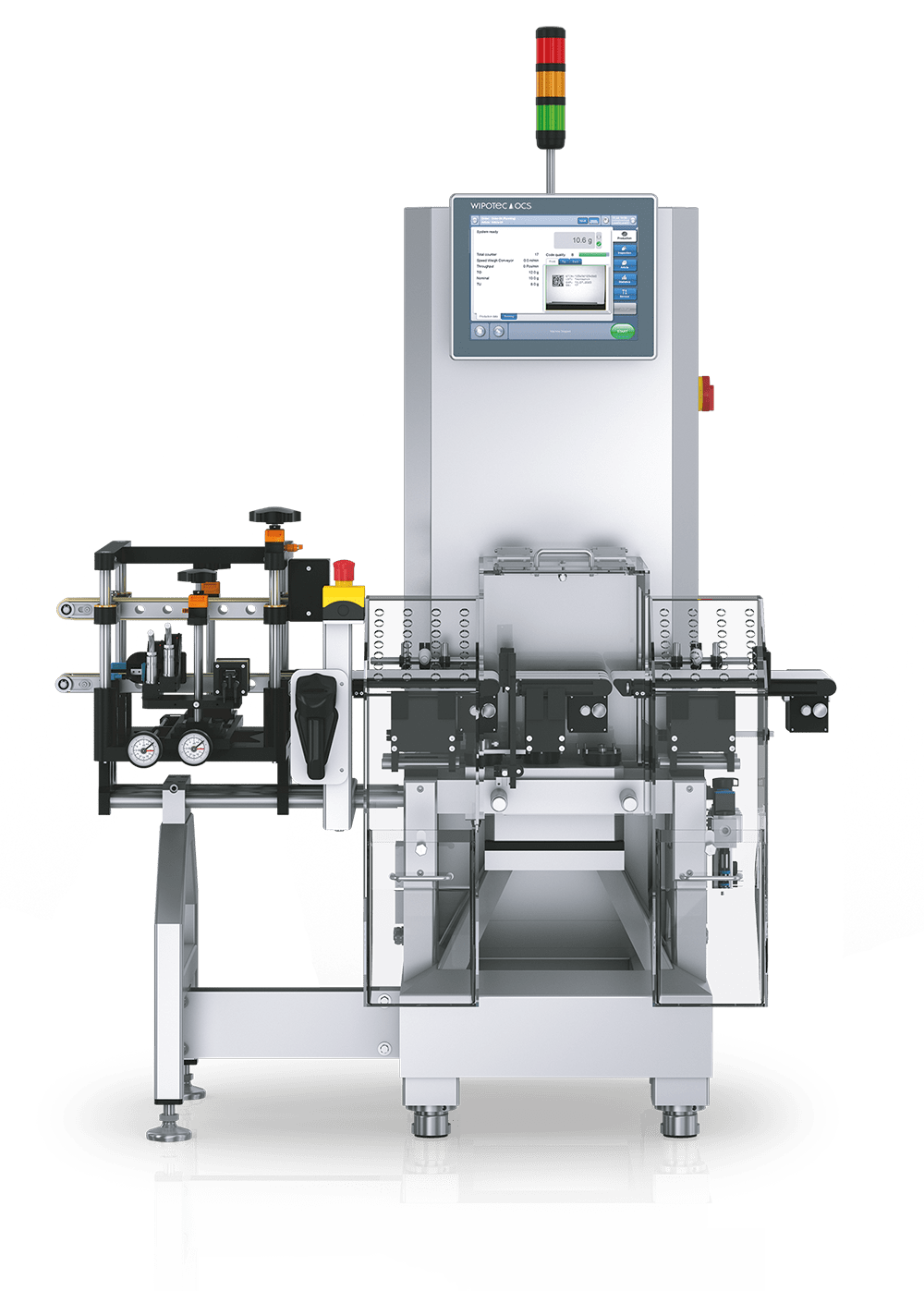

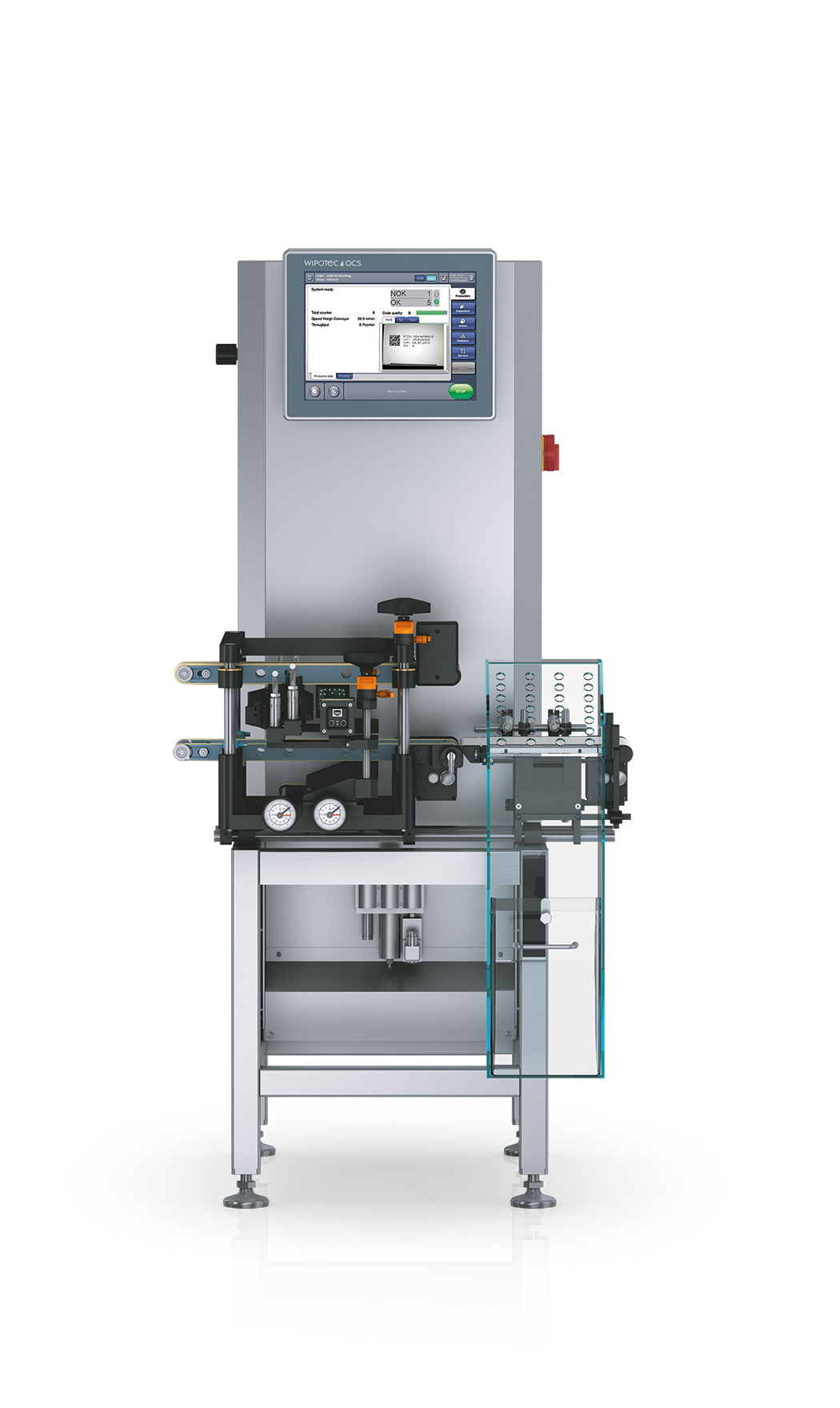

Designed specifically for the TQS product series, the top belt features continuous height and width adjustments to ensure the safe transfer of the folding boxes and provide the necessary forced guidance. The sprocket belts for the conveyor are coated with a special, high grip rubber surface that provides optimal hold of the packages. Small tolerances are balanced in elevation of the boxes. This construction eliminates slippage and movement of the packages during printing. In addition, this ensures highly accurate printing and verification, which can be increased even more with the aid of an optional synchronisation sensor. All TQS machines feature high precision product transport, which enables extremely accurate coding even at a high throughput rate. The safe transport of all packages is ensured by the time-tested NT belt technology, which also serves as the basis of high precision weighing. The use of proven modular systems facilitates the implementation of a very broad range of product dimensions.

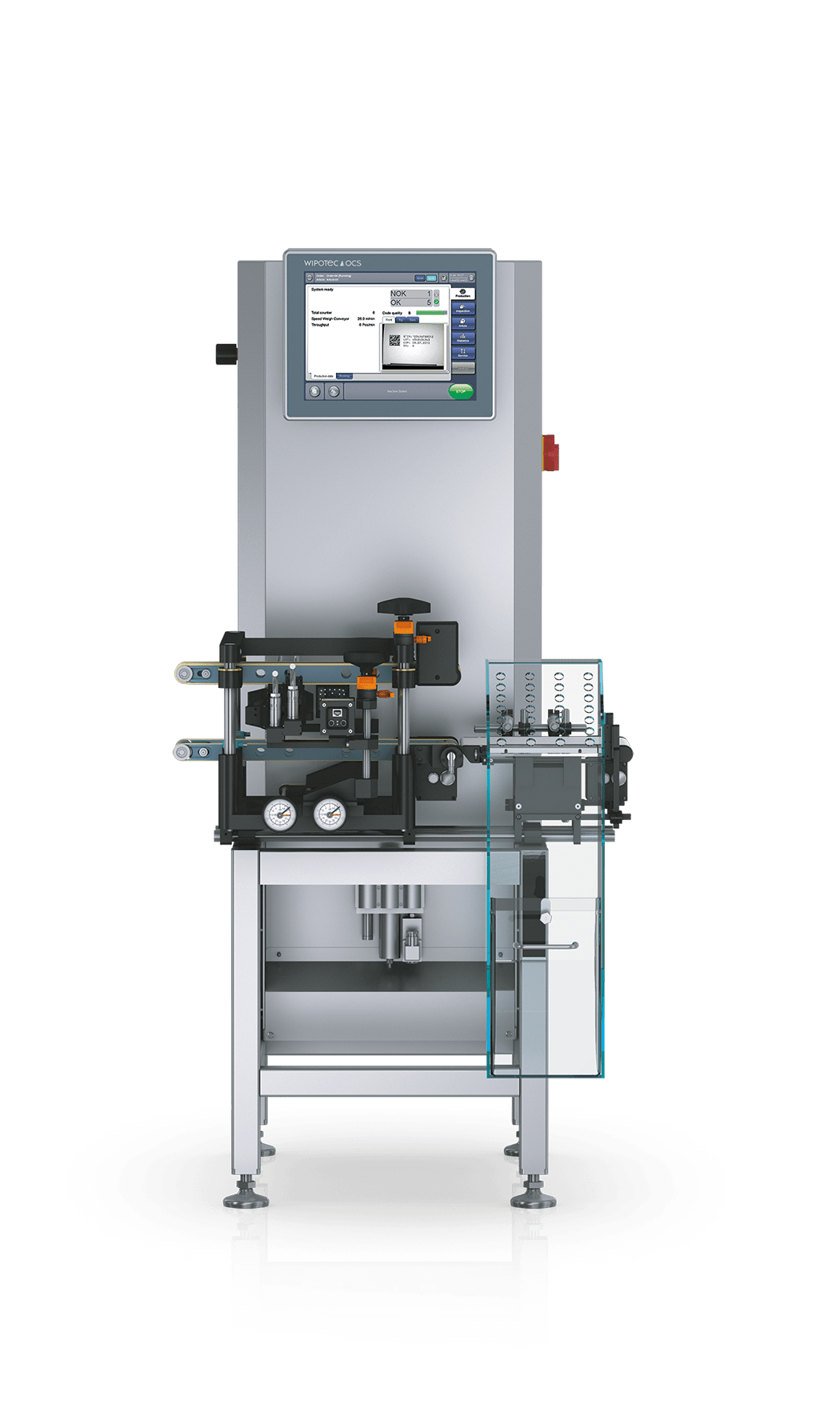

IN-LINE GRADING

All TQS serialisation machines (TQS-SP and TQS-HC-A) are designed with a function that checks the print quality of the printed codes in line. This control (grading) takes place continuously during throughput of the packages and is based on ISO/IEC 15415 (for 2D Codes) and 15416 (for 1D Codes). This evaluation is a good indicator of the print quality and is useful as a trend indicator. In-line grading does not replace the full scale, standardised verification of the printing results.

ConfigureFast: FOR QUICK AND EASY HANDLING

With flexible and intuitive operations thanks to ConfigureFast, TQS provides maximum ease of use. In ConfigureFast, the transport system, coding unit, camera, scales and labeller are all controlled with a single software. This ensures convenient setups and short changeover times for the operator when switching products, as the usual irritating need to change to various user interfaces is eliminated. This consistency extends to all levels of aggregation.

VERIFICATION

To comply with the applicable standards ISO 15415 (for 2D codes) and 15416 (for 1D codes) for off-line verification of print quality (grading), we provide a code verifier. Depending on code geometry and dimensions, this can be selected and ordered as an application-specific option.

TAMPER-EVIDENT SEALS

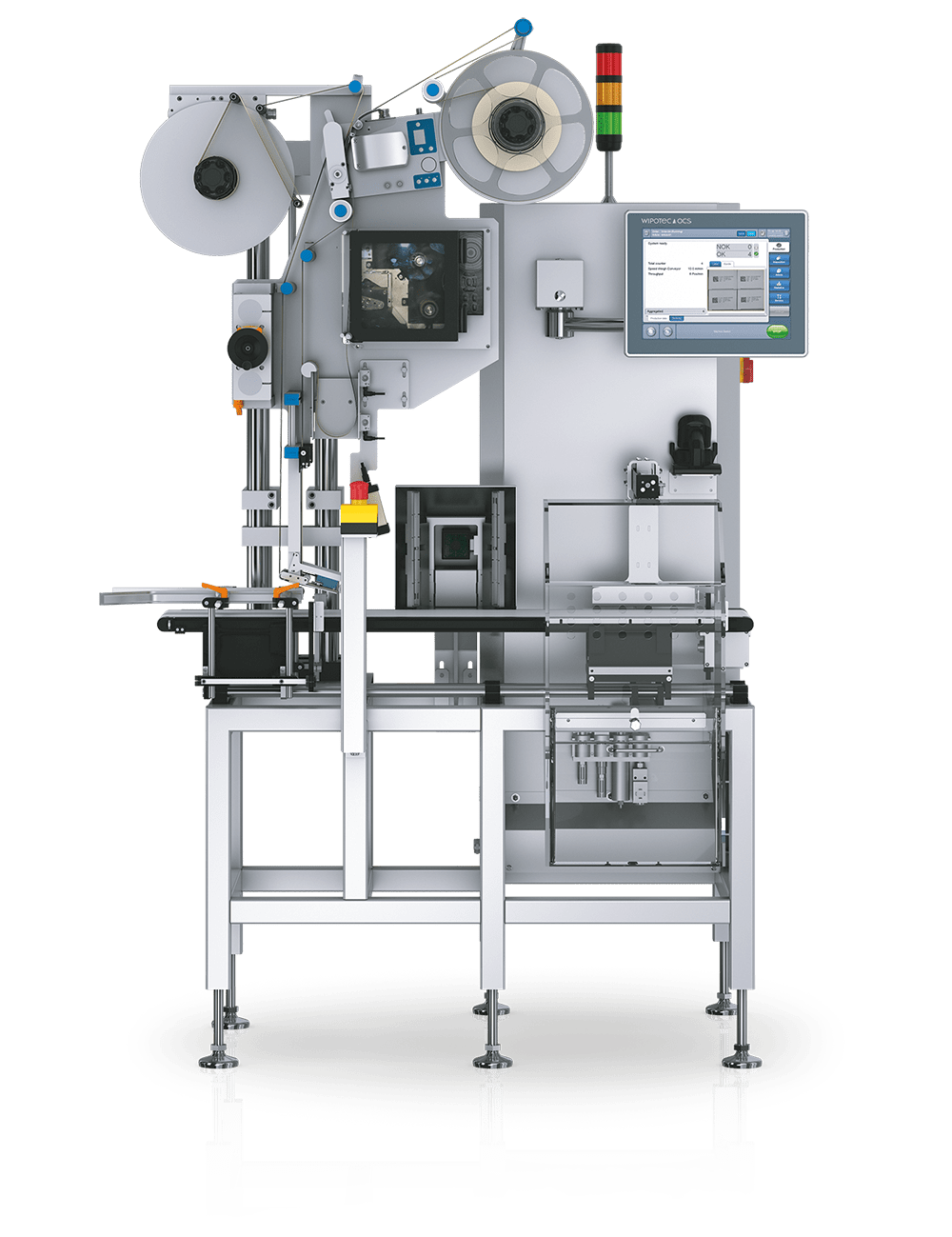

A key component in meeting European regulations regarding drug safety, is the application of a Tamper-Evident seal on every individual package. The Tamper-Evident seal can be implemented in various ways. The serialisation modules TQS-SP and TQS-HC-A use our very compact Tamper-Evident labeller to apply the safety seals. Our unique top belt system gives the necessary support to the packages.

IN-LINE THERMO TRANSFER PRINTING OF LABELS

It is necessary in some applications to provide the individual packages with an additional, country-specific label or vignette. This step is also performed in the TQS-SP and TQS-HC-A machines by means of space-saving labelling units. There is an option of using thermal transfer printing facilitates, for example, the flexible printing of batch data.