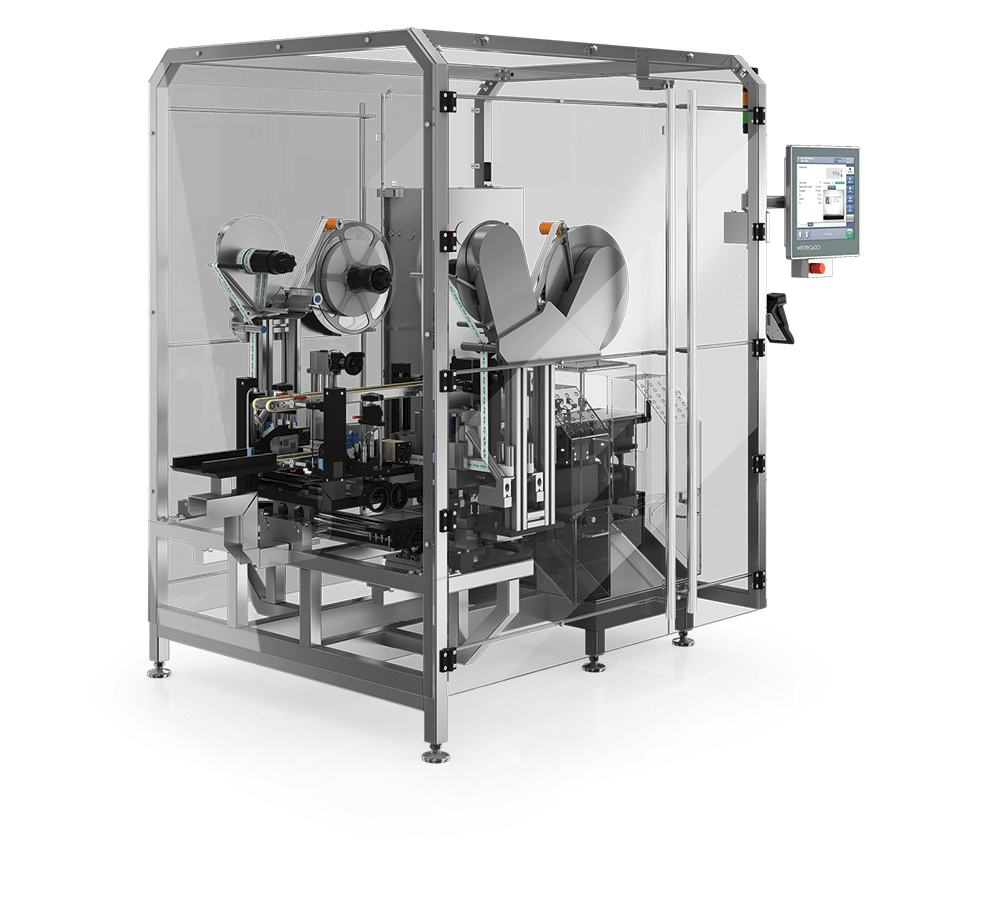

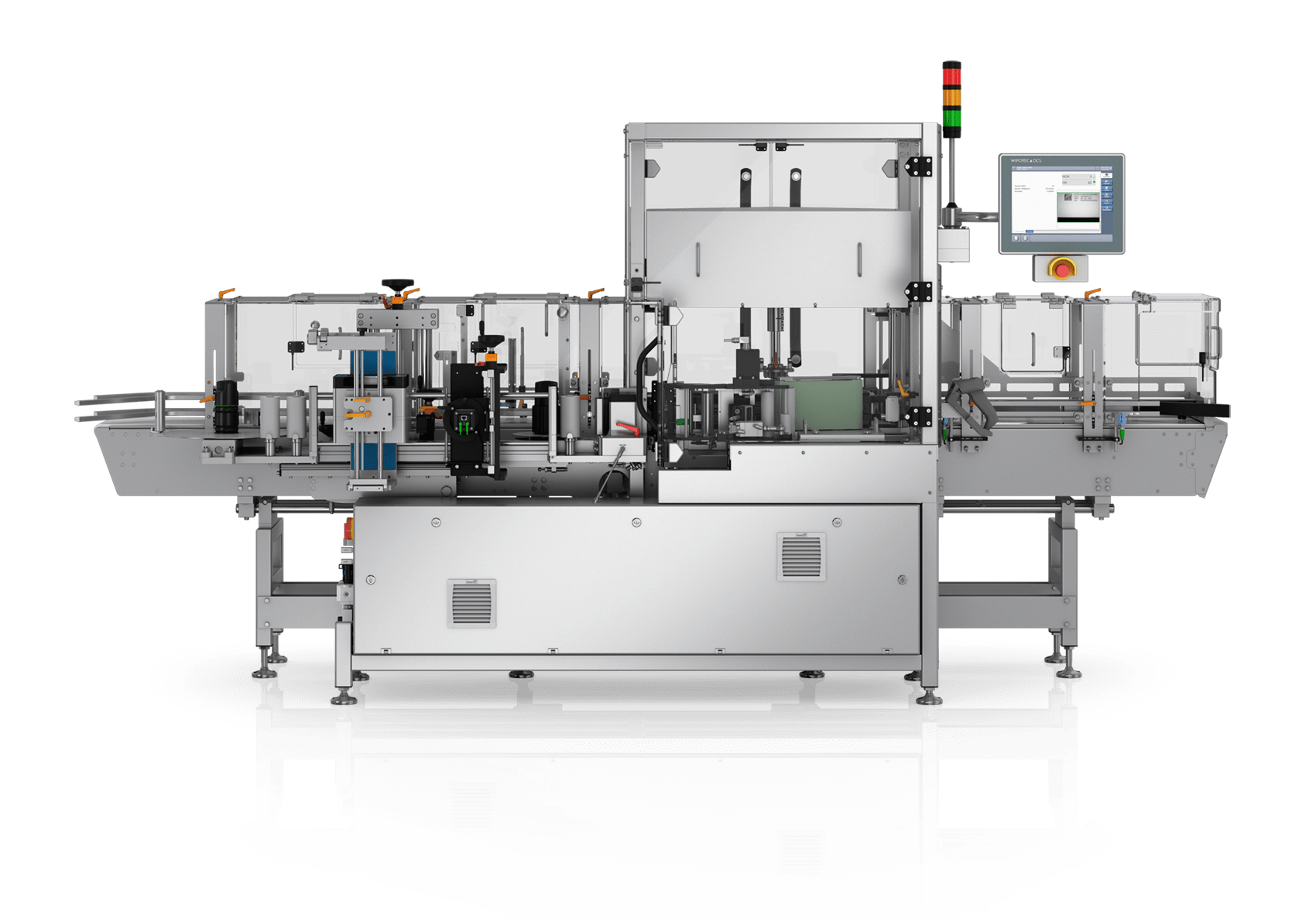

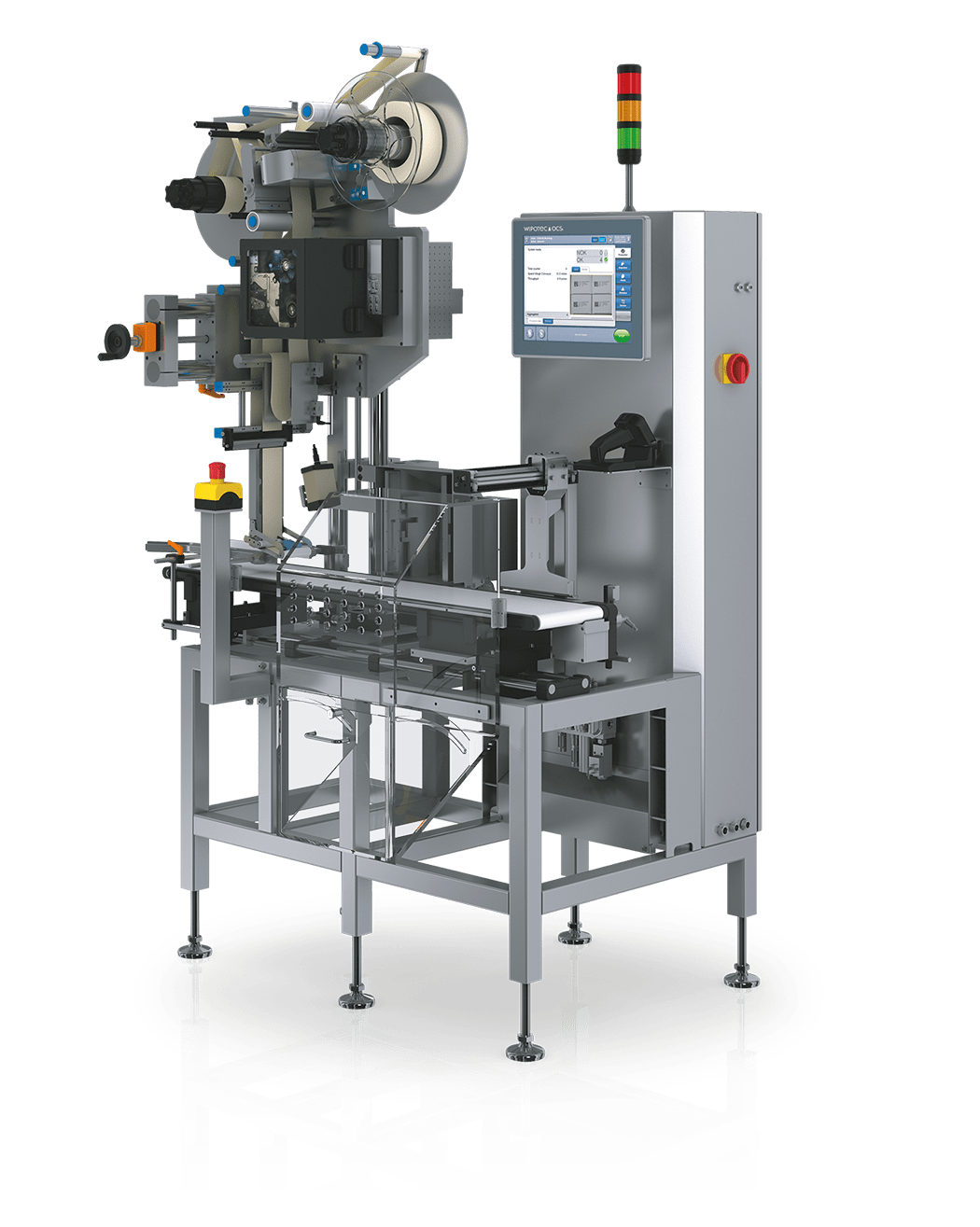

TQS-BP is perfectly equipped for the simple implementation of the first aggregation level. The system enables the serial numbers from multiple single packages to be combined to form one unique serial number for the set. The model has a format independent transport and reading system. The bundles are received directly from the bundler or, can also be manually introduced. The machine‘s intelligent code ID provides optimal flexibility, even with any eventual variations in geometry. Regardless of whether the packaged sets are rounded by stretch wrapping, shrink wrapped, or fully overwrapped, they can be reliably and safely read by means of the optional UV camera. As a supplement to TQS-BP, we supplies a fully automated grouping table that facilitates placing the sets or bundles into rows in preparation for packing or even aggregation to the next higher packaging level (for example, shipment cartons). The grouping table requires no separate configuration as it is controlled by the respective TQS machine.

Key Features

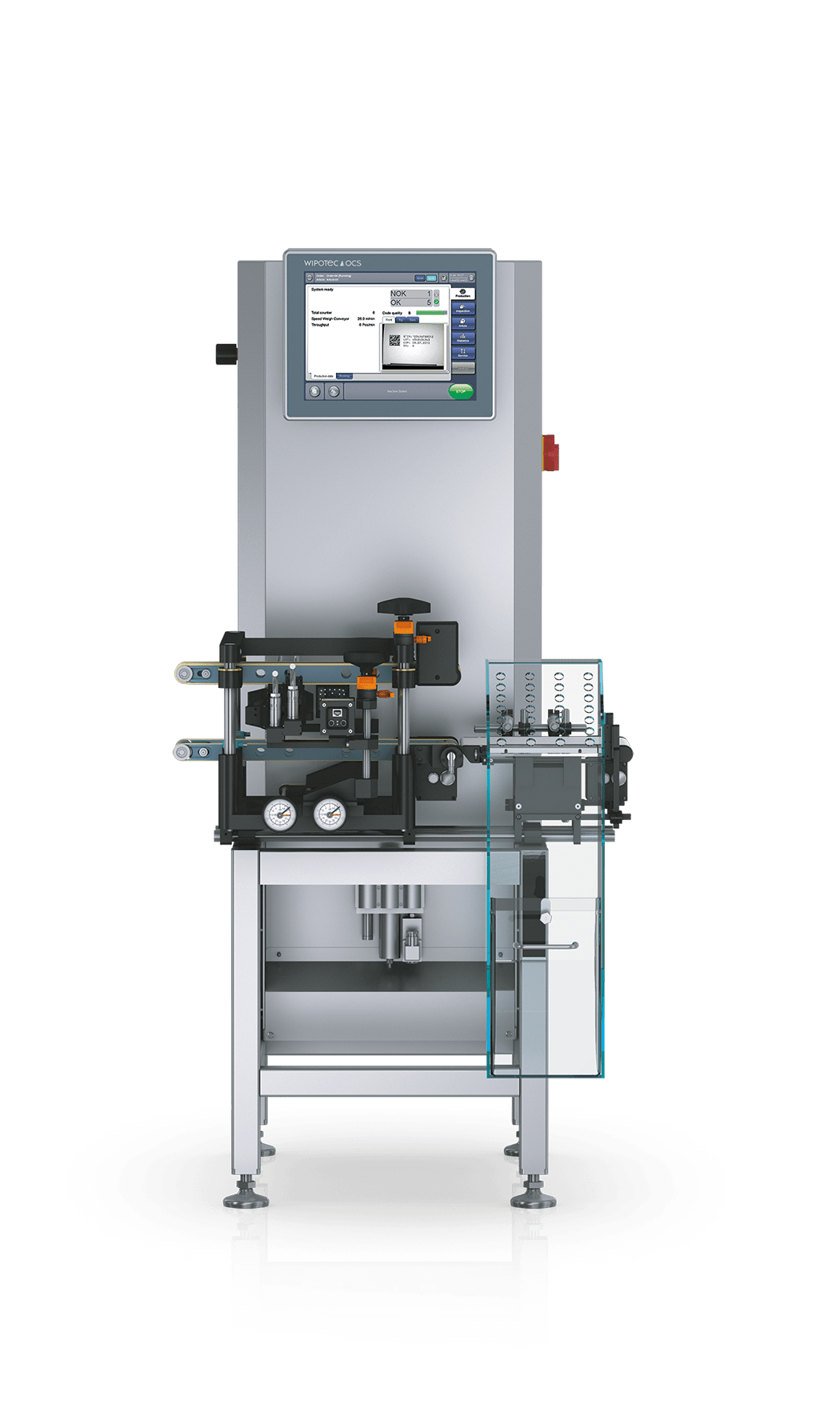

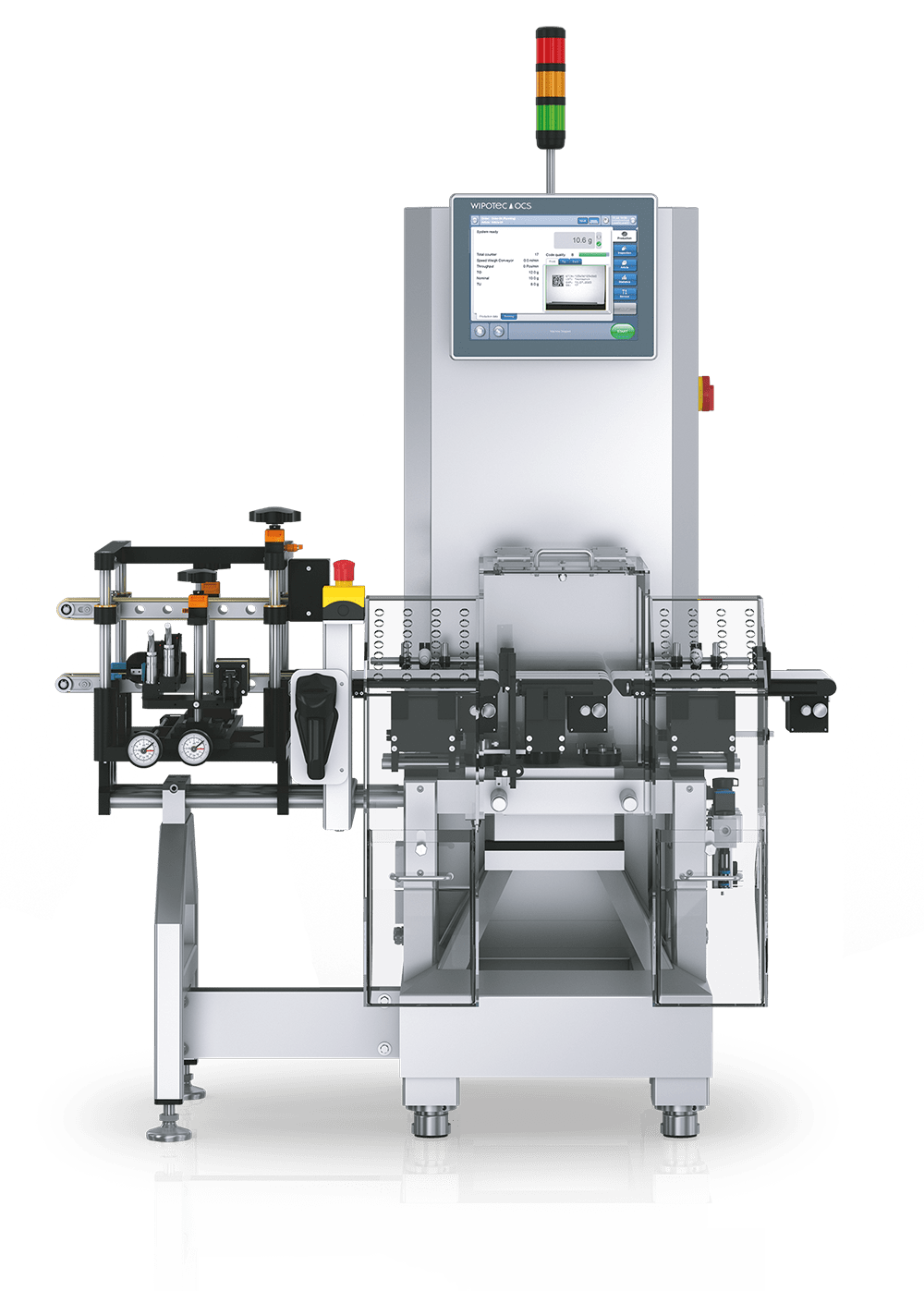

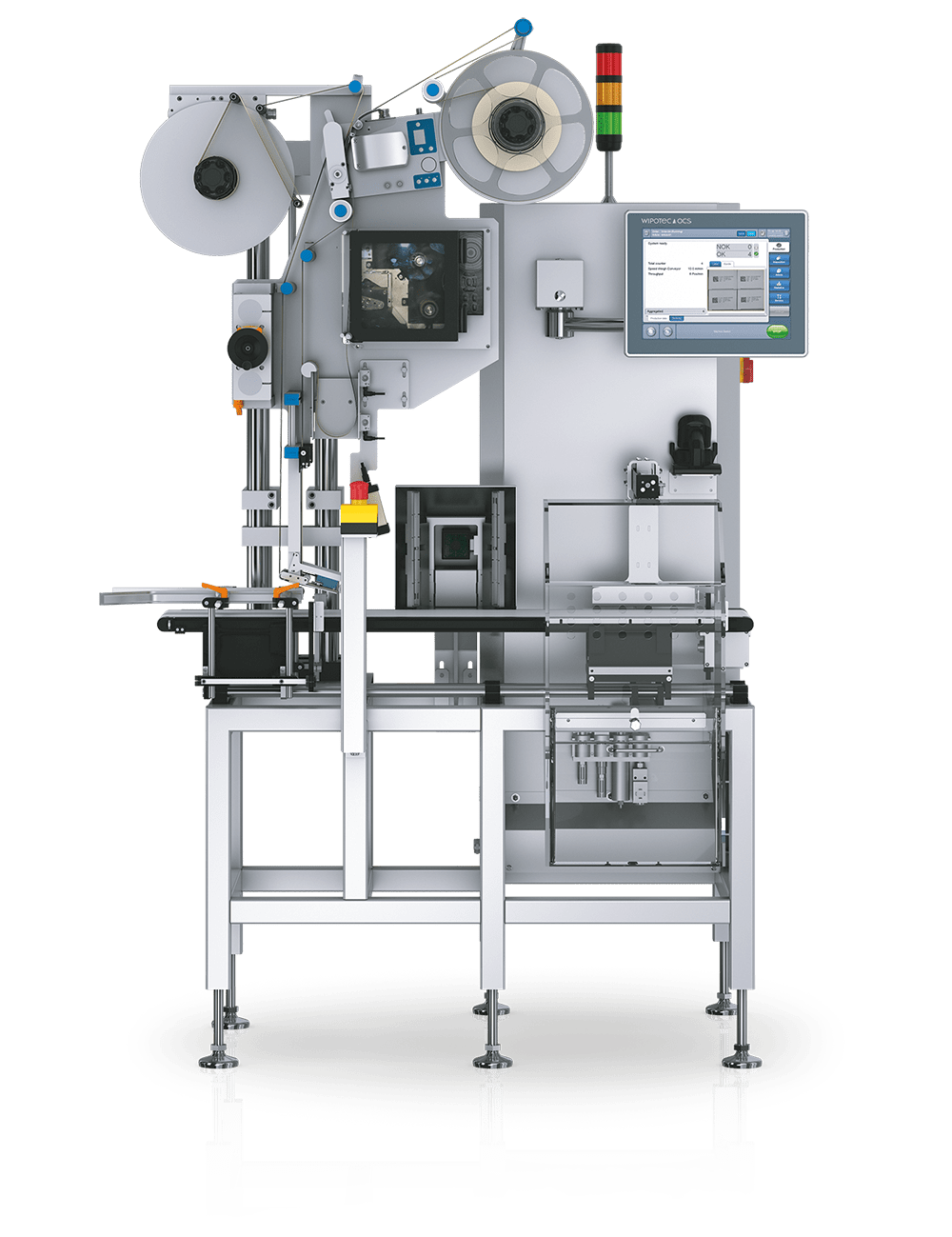

- Fully integrated label printer and applicator unit, incl. camera control

- High performance TQS VIO 2 camera for precise code verification

- Handheld scanner for manual read in and changing aggregation hierarchies

- Reliable discharge by means of the traction pusher

- Large 15” with touchscreen display and intuitive control menu (19” optional)

- Validation packets and documentation IQ/OQ, FDS, RA, TM (optional)

- Camera mounts front and back (optional)

- Tool free format change

YOUR BENEFITS

- All-in-one operations concept for quick and easy handling

- Space saving design facilitates integration in existing lines

- High throughput rate (up to 75 pcs/min, 30 pcs/min standard) enables significant increase in productivity

Ask about the product