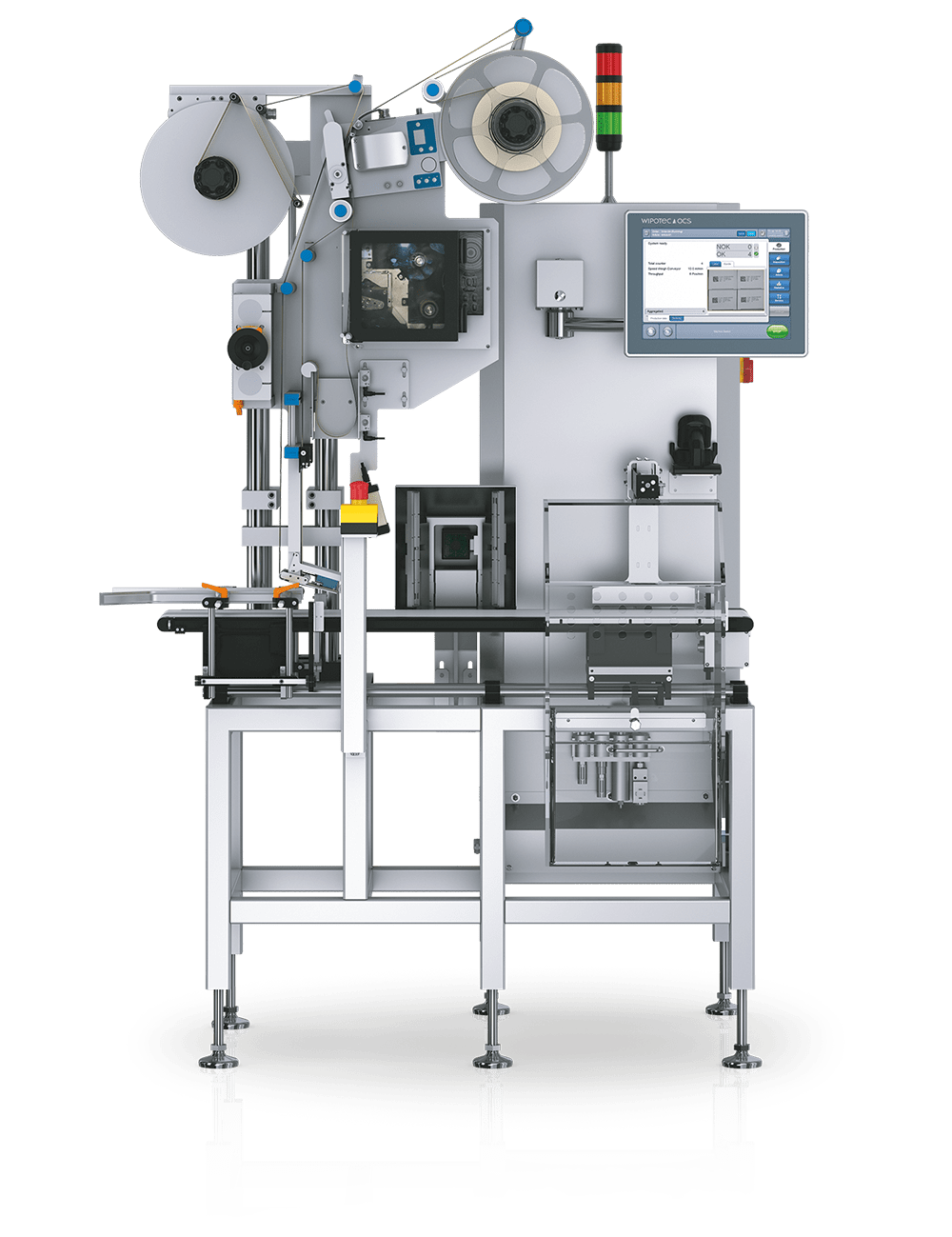

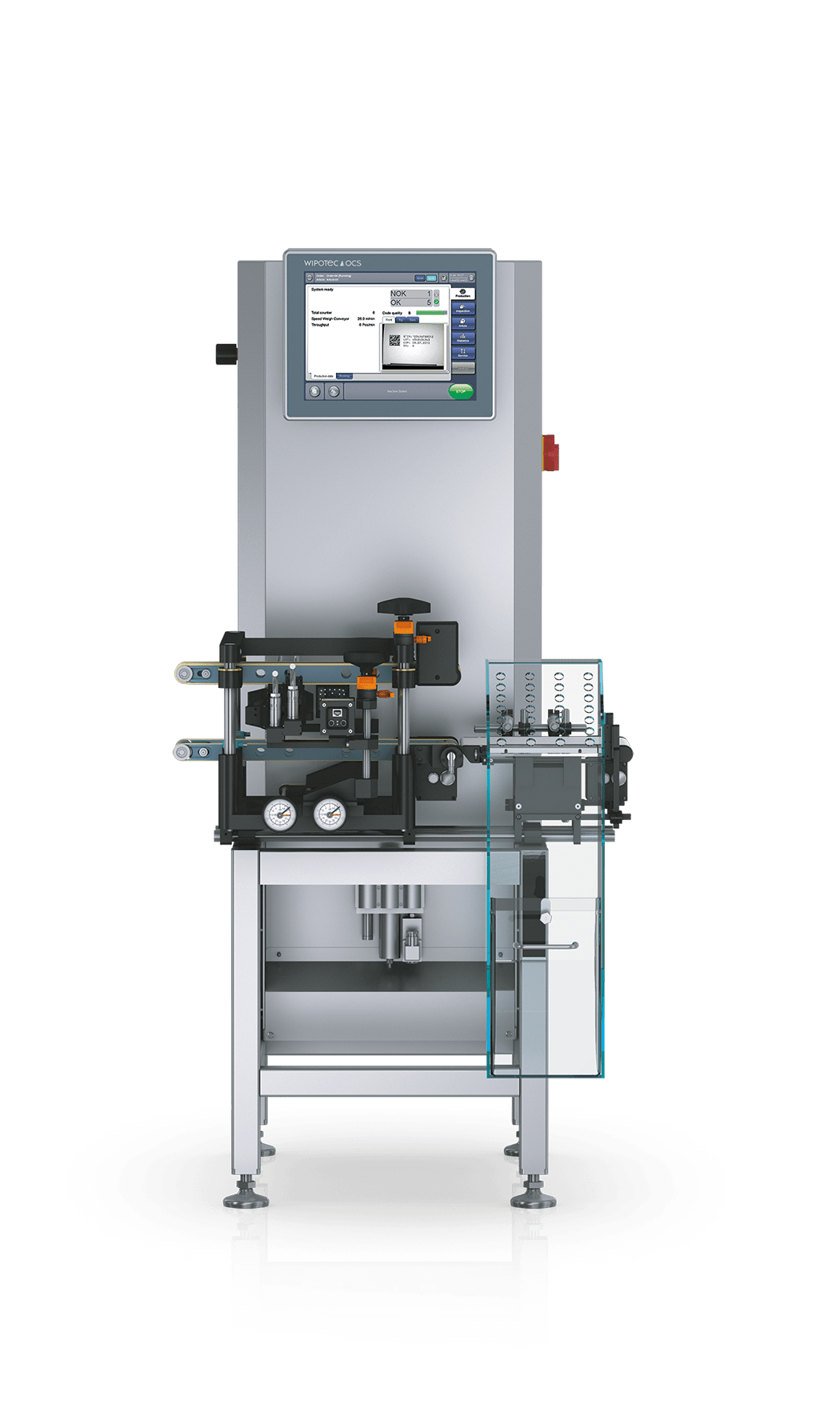

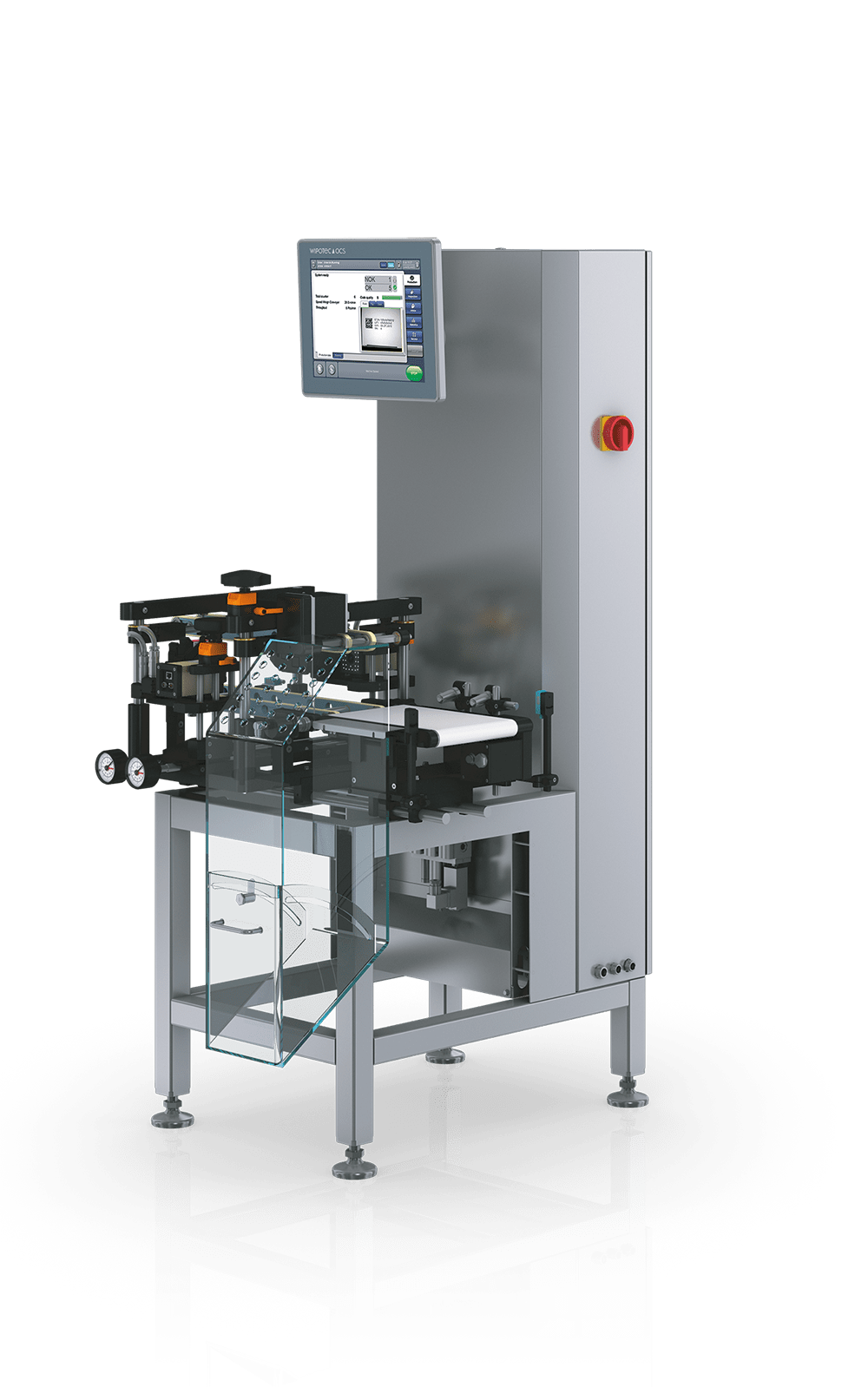

TQS-SP is a user friendly solution for the serialisation of individual cartons. The folding boxes are conveyed by a specially designed, double guided top band system that ensures stable positioning after leaving the cartoner.

The TQS top bottom band is fully adjustable in three dimensions to quickly and easily accommodate various carton formats. The labels are applied as required on the flaps (front or back side) or the top of the folding boxes. The TQS-SP can be installed into a line network with automated product feed or as a mobile stand-alone unit with manual supply. The unit can be retro fitted into any existing packaging line. Thanks to ConfigureFast, identical print data is sent directly to the printer and to the camera‘s print imager. All system components are quickly and easily controlled from one single user interface without having to switch programs. As an option for the TQS-SP, TQS-HC-A and TQS-BP, we supplies a fully automated grouping table that facilitates placing the folding boxes or bundles into rows in preparation for packing or even aggregation to the next higher packaging level (for example, shipment carton). The grouping table does not require any separate setup. It is controlled from the TQS machine.

Key Features

- Stable transfer positioning of folding boxes and guided transport for safe and optimal printing and reading results

- TQS InkPrint printer with print head and fully integrated user guides

- TQS VIO1 camera with fully integrated user guides

- Flexible print head/camera mounting position

- Large 15” with touchscreen display and intuitive control menu (19” optional)

- Validation packets and documentation IQ/OQ, FDS, RA, TM (optional)

- Tool free format change

YOUR BENEFITS

- All-in-one operations concept for quick and easy handling

- High throughput rate of up to 600 pcs/min (300 pcs/min is standard)

- Space-saving unit for quick integration and operational readiness helps achieve cost reductions

Ask about the product

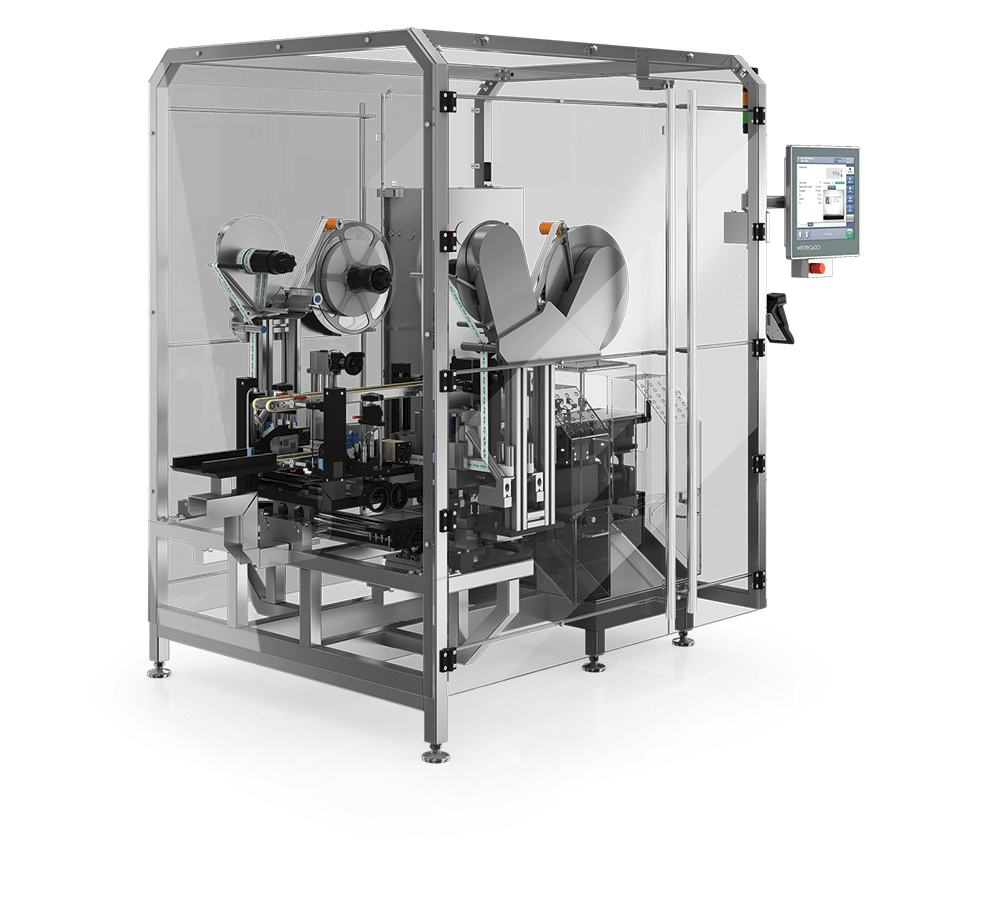

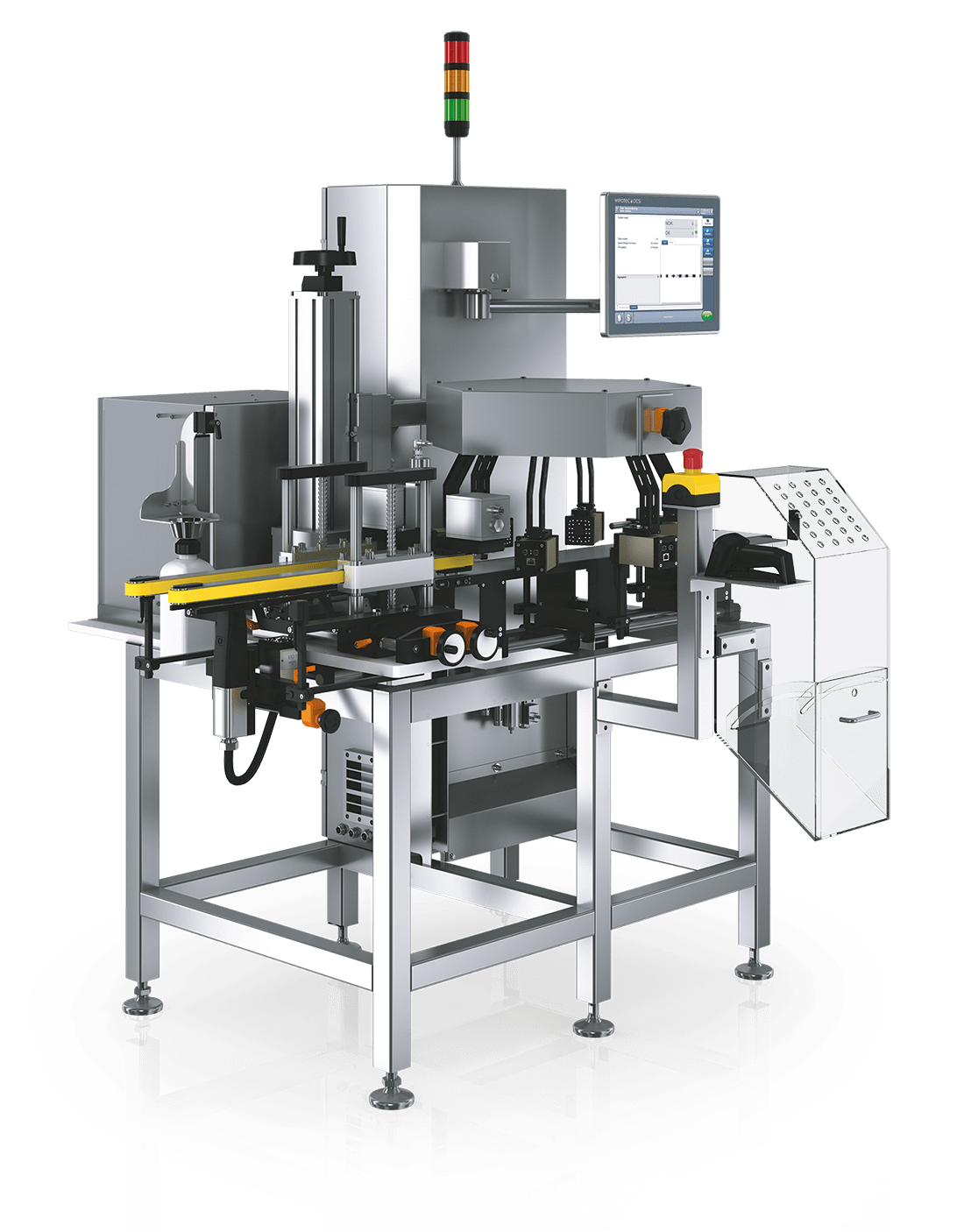

TQS-SP-Bottle

TQS-SP-Bottle prints auxiliary codes and verifies bottles and vials. Printing is completed by the CIJ printer either on the underside or the top of the container (visible only under UV light, if required). Subsequently, the machine verifies the previously serialized bottle or vial labels. The auxiliary aggregation code is for the higher-level aggregation in bundles or cartons. Additionally, the integrated 360° camera unit manages the all-round inspection of cylindrical objects, for example, the optical control of the coding, layout, and plain text on vials or bottles. Multiple ultrafast cameras are used for the omnidirectional detection of the objects. Coded containers with faulty labels or an incorrect auxiliary code are separately ejected from the product flow and stored in lockable containers. ConfigureFast will quickly and easily configure all sub-components, like the printer and camera, from a single interface.

Key Features

- Integrated 360° camera module for ultra-fast inspection (aggregation)

- Central adjustment unit for easy camera set up

- Secure product handling and separation of cylindrical objects through side pressing belt for superior printing

- and inspection results

- UV Helper code marking with CIJ printer and inspection

- Validation packets and documentation IQ/OQ, FDS, RA, TM

- Tool free format change

- Fastest configuration with ConfigureFast

YOUR BENEFITS

- All-in-one operations concept for quick and easy handling

- Compact, high-tech, multi-functional unit for optimal productivity

- High throughput rate of up to 500 pcs/min (300 pcs/min is standard

- Maximal integration flexibility through modular design